Manufacturing

Home / Manufacturing

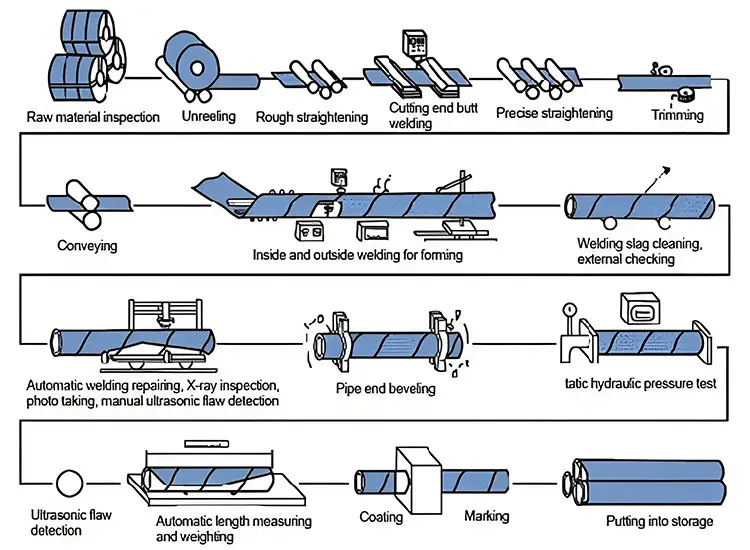

Spiral Welded Pipe (SSAW)

1.Uncoiling and Straightening: We need to have our carefully-selected steel plates of top quality straightened using the straightening machine to make them flat and straight, which…

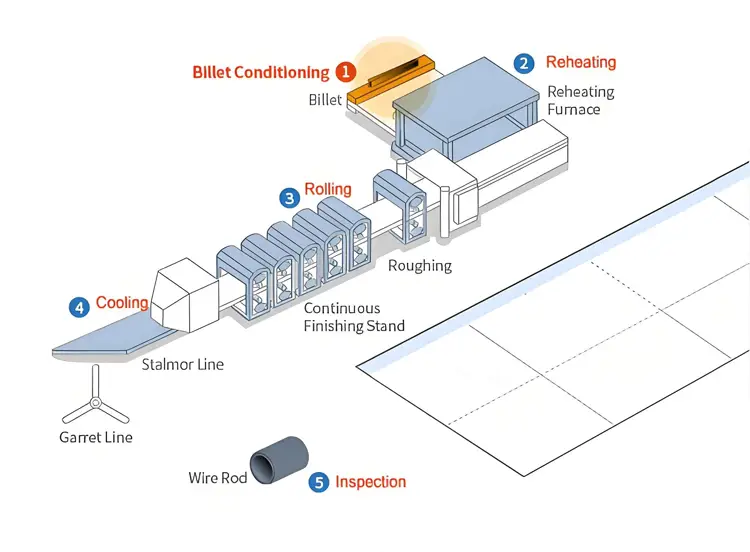

Wire Rod

1.Billet Conditioning: This process is intended for checking thesurface quality of billet and removing any defects, Shot blast is usedto remove any scale from the surface, Magnet particle testing and…

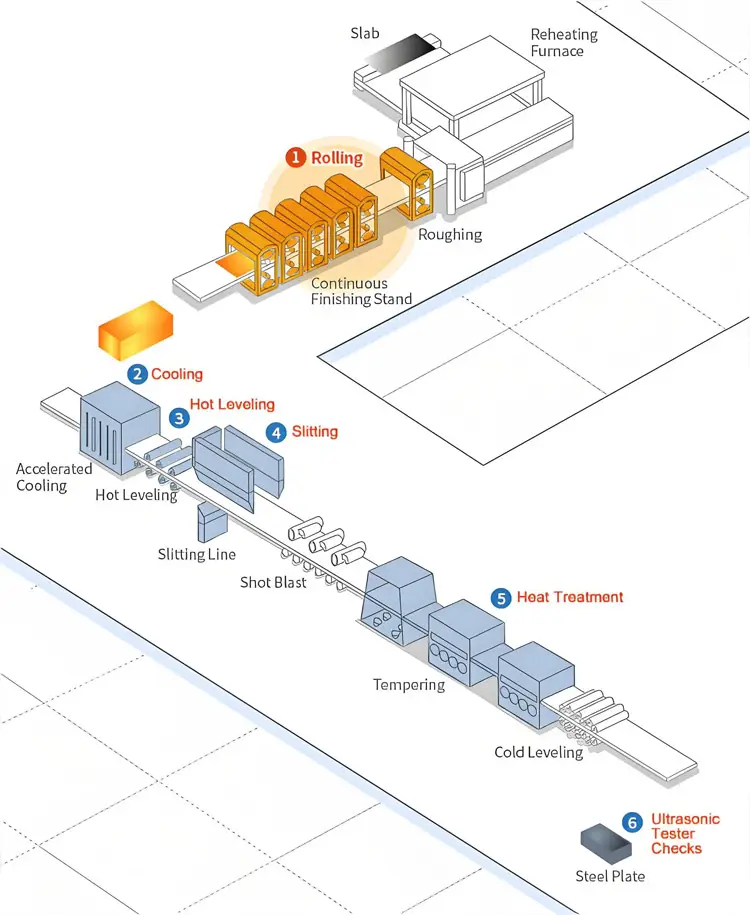

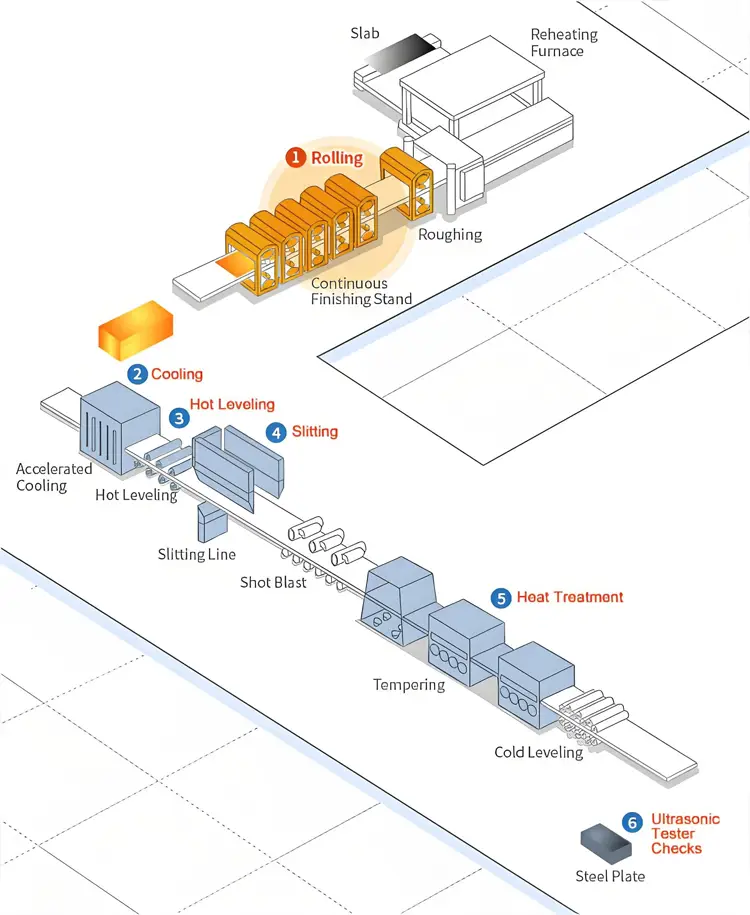

Steel Plate

1.Rolling: The 4-high reversible finishing mill with the maximum loadof 7000 tons minimizes internal defects even inly thick plates.Automatic gauge control and shape control systems can reduce no…

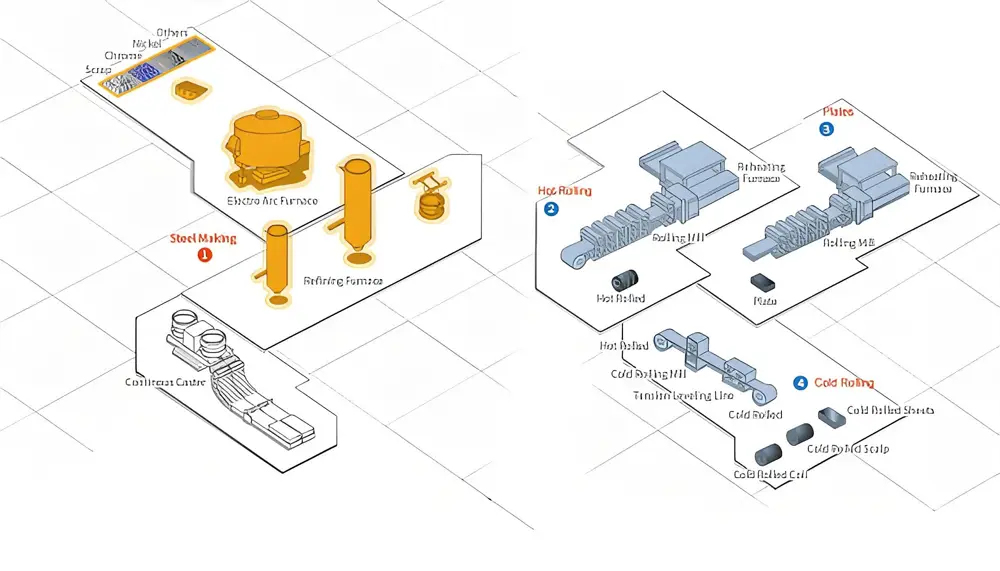

Stainless Steel

1.Steel Making: Steelmaking has the greatest impact on the qualityand cost of steel products. We has state-of-the-art AOD, VoD andcontinuous casting facilities…

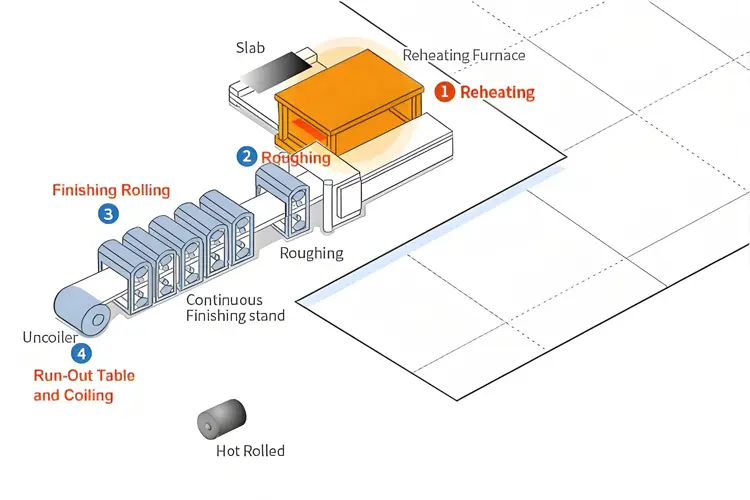

Hot Rolled Steel

1.Reheating: Hot rolled coils pass through a pickling line, wherescale breaker machines and hydrochloric acid solutions are used toremove any surface scale and/or oxide film that which causes…

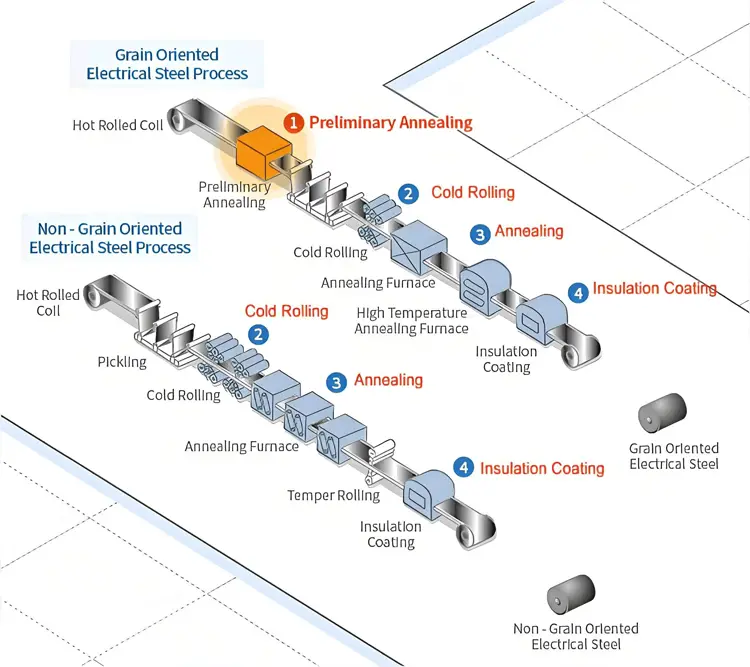

Electrical Steel

1.Preliminary Annealing: During the preliminary annealing process,a scale which may have formed on the hot rolled steel is removed asdelayed passing through scale breaker and a hydrochloric acid bat…

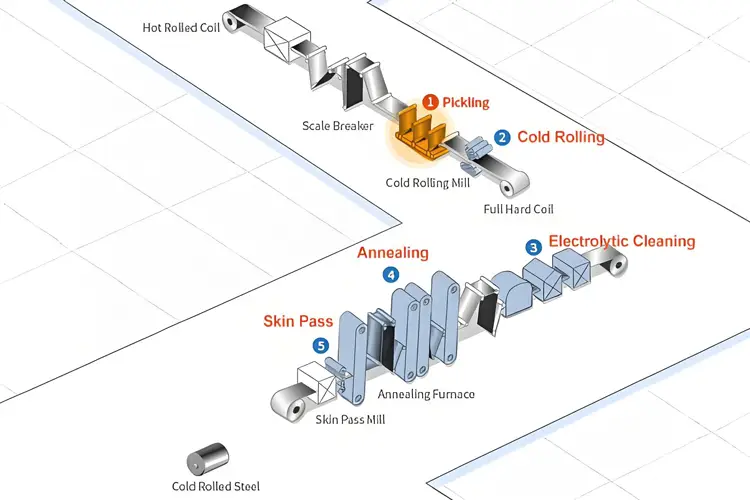

Cold Rolled Steel

1.Pickling: Hot rolled coils pass through a pickling line, where scalebreaker machines and hydrochloric acid solutions are used toremove any surface scale and/or oxide film that which causes…

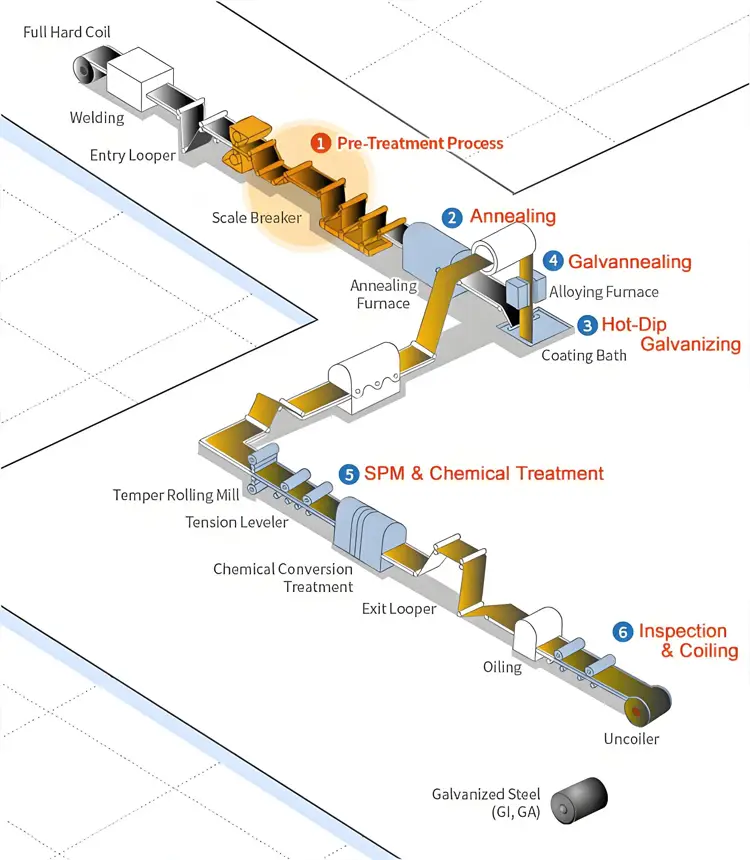

Galvanized Steel

1.Pre-Treatment Process: Some rolling oil and other contaminantsremain on the surface of cold rolled steel sheets followingprocessing.These are removed by passing the electrically charged…

Electrical Galvanized Steel

1.Input Process: Equipment at the entry point of theelectrogalvanizing line consists of a pay-off reel, a shearing M/C, awelding M/C, a looper and a tension leveler, The pay-off reel…