About Us

Founded in 1989

Established in 1989, Futai Steel supplies a wide range of carbon, alloy, and stainless steel products, including high-speed tool steel, cold work tool steel, hot work tool steel, plastic mold steel, engineering steel, and machinery structural steel. After nearly two decades of development and growth, Futai Steel has become a comprehensive special steel mill, stockist, and exporter. With an experienced export team and professional technical knowledge, Futai Steel offers technical advice and support, as well as global professional steel solutions and services. Thanks to reliable quality assurance and professional services, Futai has expanded its market worldwide, including countries such as the United Arab Emirates, Canada, Brazil, Colombia, Chile, Spain, Turkey, Algeria, Vietnam, Malaysia, and more.

Our Mission, Philosophy & Vision

Our Company Mission

Since its establishment, Futai Steel has been dedicated to becoming one of the world’s leading suppliers of special steel. We persist in providing reliable and superior quality high-speed tool steel, cold work tool steel, hot work tool steel, plastic mold steel, as well as alloy and carbon engineering steel for industrial, military, and other applications.

The philosophy of Aotai Steel

Quality is Futai Steel’s life. Reliability is Futai Steel’s code. Customer satisfaction is Futai’s ultimate goal.

Futai Steel’s Vision

Futai Special Steel Co., Ltd. aims to establish broad, solid, long-term strategic partnerships with global customers on the basis of mutual benefit.

We Specialize in Tool Steel & Alloy Steel

High Speed Steel

Futai supplies AISI M2, M35, M42, and other high-speed steels. High-speed steels are widely used in saws, planers, high-speed milling cutters, and other special applications.

Hot Works Tool Steel

Futai Steel provides hot work steel such as AISI H13, H11, H21, etc. These steels are widely used in aluminum die casting, stamping molds, forging molds, and more.

Cold Works Tool Steel

Futai Steel supplies cold work mould steel in AISI D2, D3, O1, A2 etc. It’s widely used for punch mold, knife mould, screw mold, rolling roller etc.

Plastic Mould Steel

Futai supplies AISI P20, P20+S, NAK80 etc for pre-hardened pouring mold, mold of polishing glasses, mould of mirror surface. etc.

Engineering Steel

Futai steel supplies AISI 1045,4140, 4130, 4340, 52100, etc. It’s widely used in aerospace, industrial engineering, mechanical industry.

Processing & Design

Cut to Size Service

We could supply cut to size service for tool steel and engineering steel, according to given size and dimension. This would save your energy and labour cost, we could supply your final required size.

Machining

Make per Drawing

Design and Consulting

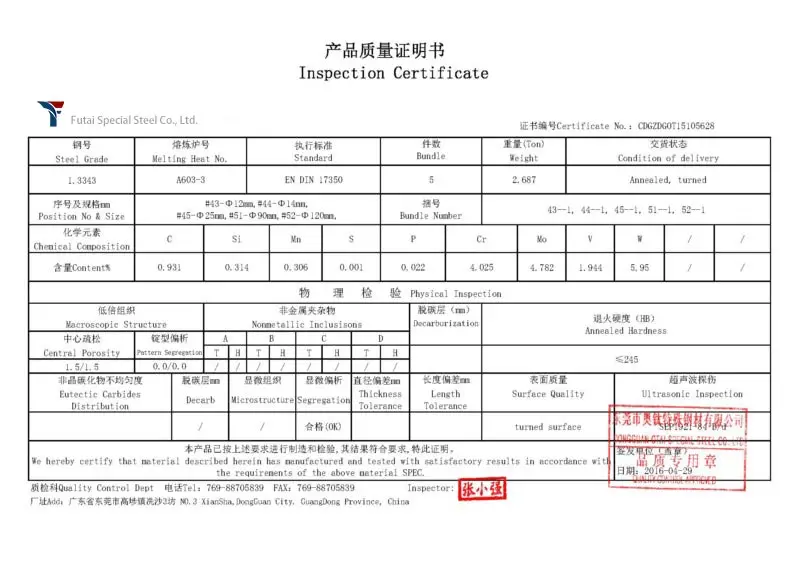

ISO9001:2015 Quality Control